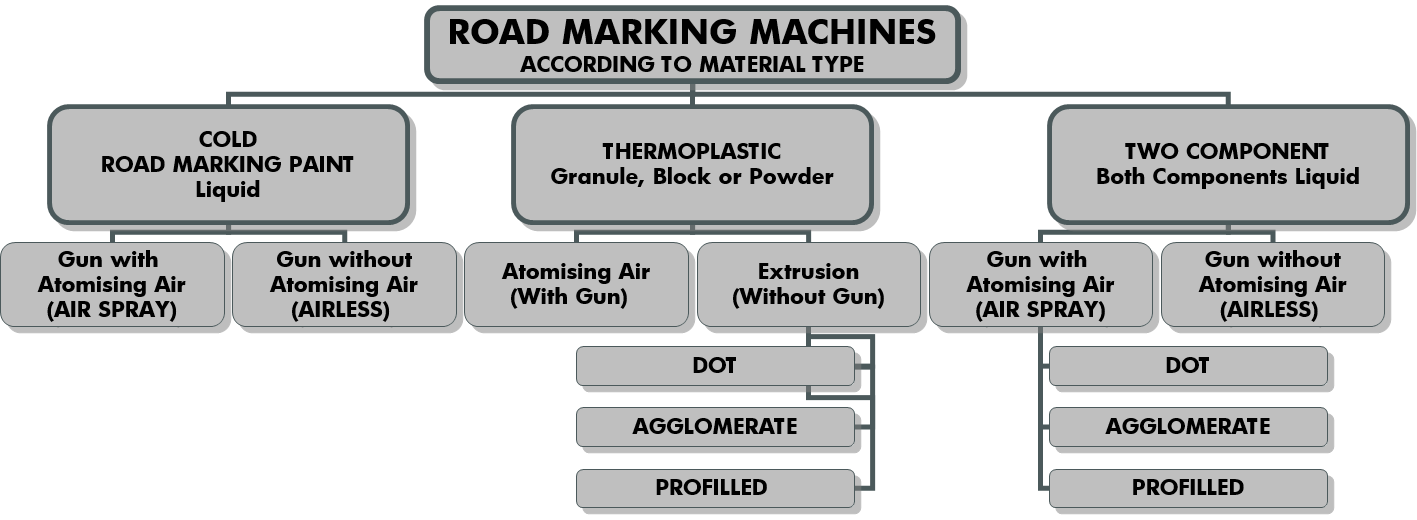

Traffic markings, which started in the beginning of 20th century in U.S.A and England, in order to warn drivers in the risky crossings with hand applied markings, become legal requirement in time. Road marking machines are the equipments to apply road markings with paint and other chemicals produces specifically for that purpose, with the aim to directing and warning pedestarians and vehicles moving along roads.

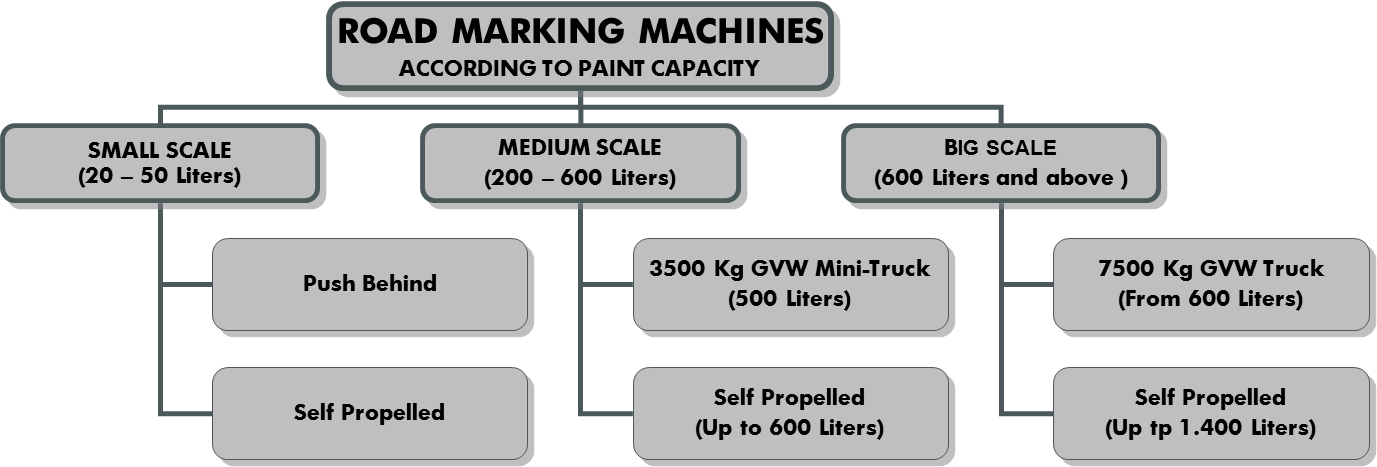

Working of Road Making Machines are based on the principle to apply the paint stored on the tank of the machine, to form a lane on the surfeace of the road. This operation, based on the requirement, can be applied both by small scale push behind machines, and for bigger capacities, by big scale and truck mounted equipments. Main factor on classificafion of Road Marking machines are based on the kind of paint to be applied.

Road marking machines applying cold paint

Water or solvent based cold road marking paints can be applied by two different systems called; Air Spray and Airless. Paint in the Air Spray System is kept under compressed air pressure in a tank; (5-8 bars) and delivered to paint guns under this pressure. Paint reached to paint guns, are atomized by an air pressure connection in the paint guns and sprayed over the road surface with this pressure. Air spray can also be applied by keeping the paint in an atmosphere pressure in a tank and delivering to paint guns by low pressure paint pump. Briefly, Air Spray Sytem is based on the principle to apply low pressure paint by atomizing pressurized air in the paint guns. Advantage of this system appears with the ability of paint guns to make application with high flow rates, which obtain operating at high speeds. Also, it is possible to make application with glass beads mixed into paint when the right paint guns are being used.

In the Airless System; paint stored in a tank under athmosphere pressure and delivered to paint guns via a paint pump with a high pressure (around 200 bars). With the high pressure, there is no need for additional pressure to atomize the paint. That is the reason why that system is called Airless System. Main advantages of Airless Sytem are that, applied marking on the road will be sharp on the edges and that the paint consumption will be less compared to Air Spray.

Road marking machines applying thermoplastic

Granule, block, or powder thermoplastic materials, are applied to the road surface in a liquid form, with these machines by melting these materials through heating up to approx. 200 °C. Main difference of Thermoplastic Road Marking machines is that the tank in which paint stored is basicly a hot oil boiler. Heat transfer oil in the chambers of the tank is heated by a burner on the tank and the thermoplastic material in the tank is indirectly heated to application temperature via this heat transfer oil. These machines can spray the heated thermoplastic material, transferring the material to its guns either with air pressure in the tanks or with a low pressure pump.

Besides, extrusion road marking application can be done with special hand application tools by pouring the material under atmosphere pressure.

With automatic extrusion shutters, it is possible to apply making applications like; Dots, Comb or Checks, besides straight and broken lines.

Especially Dot marking applicaiton, with its success for visibility performance compared to straight lines, increased the attention for Dot application technology. Given that heating of the thermoplastic material is needed prior the application, thermoplastic road marking machine owners, and companies also require thermoplastic preheaters. Thermoplastic preheaters have the same specifications with the tanks on the Thermoplastic Road Marking Machines. Preheaters keep the paint ready for supplying while Thermoplastic Road Marking machine is operating.

Road marking machines applying 2 component paint

These machines are designed for materials which are prepared for application by mixing more then one component (mostly two components). Working principle of these machines are based on mixing two components within the machine and delivering to the paint guns. Initially, applications were completed with machines mixing the components with 1:1 ratio; however new generation machines can mix and apply two components with 98:2 ratio. Thus, a smaller tank for second component (hardener) will be sufficent. These machines, likewise Road Marking Machines applying Cold Paint, can work with both Air Spray and Airless systems. Advantage of Air Spray System is that besides road marking, high visibility Dot Lines application can be performed with this system. These machines have required equipments and softwares which arranges material consumption depending on speed of the machines, keeping the consumption at optimum levels.

Road Marking Machines applying 2 Component Paint; are being prefered recently due to their high technology, lifetime of the lines applied, alternative marking options of patterns and profiles, and the ability to apply the material without heating.

Main Equipments of Medium and Big Size Road Marking Machines

Another factor for selection and classification of Road Marking Machines is the capacity and attributes of the equipment. Therefore, some basic information should be considered.

Air Compressor: Regardless of the kind of the paint applied or the application method, all medium or big size machines require an air compressor. Preferred air compressor type is diesel motor driven screw compressors.

Broken lines are applied by closing and opening the paint guns while the machine is moving. Regardless of the speed of the machine, this process is controlled automatically by computer control and paint guns, glass beads guns and also extrusion and pattern equipments is controlled with pressurized air. Besides, air compressor is also required for instance equipments for cleaning the road surface with compressed air and all pneumatic control components.

Paint pump: In the Airless Systems, a paint pump is required to atomize, or break up the fluid into small droplets with high pressure. Pump transfers the paint by sucking ang pressurizing the paint with the help of a piston or diaphragm to the paint guns. These pumps can also be driven with hydraulic oil or gasoline engine, besides pressurized air. As well as Airless Systems, low pressure pumps can also be used for Air Spray Systems applying both Cold Paint, and Thermoplastic Material, in which paint is stored under athmosphere pressure in the tank.

Dry film thickness of the line on the road is one of the most important factor to consider in selection of the paint pump. Dry film thickness of the line on the road is determined by authorities in application technical specifications and holds an important role in the lifetime of the lines. Flow Rate of the paint pump should maintain required thichness level even at highest operation speeds.

Paint guns: Road marking applications are performed with paint and glass beads guns working together. In automatic controlled small scale machines, and all medium, big size road marking machines pneumatically controlled automatic paint guns are used. Meaning, paint guns are opened and closed with pressurized air. Glass beads guns are positioned behind the paint guns. Glass beads guns sprays reflective glass geads over the applied paint on the surface of the road. This helps the visibility of the road marking at nights.

Optionally, manuel guns can be used in road marking machines. Arrows, symbols or shapes can be performed using these guns. Also, these guns can be used to paint borders.

Automatic control: Broken lines applicaiton is performed with automatic control unit on the machine. Control Unit consists of; programable electronic unit, electronic speed meter and solenoid valves. Speed of the machine measured with electronic speed meter is forwarded to control unit. Control unit, using this information and earlier entered programable line lengths, controls solenoid valves, and these valves commands the paint guns. Earlier selected programable broken line lengts can be applied even for variable machine speeds.

Line and broken line measurements are determined according to particular standarts. In Turkey, these standarts are determined by General Directorate of Highways. Different standarts can be experienced in different countries.

Paint and glass beads tanks: Taking into consideration the consumption raitos, glass beads capacity of the machine should be 1/3 of the capacity of the paint tank. Application size and time plays a crucial role in determining the tank sizes of paint and glass beads.

For example, after a big road construction work, for road marking, we sould assume that there will be work for eight hours per day. Hence, selection of tank size is very important for optimal application time and for making number of times of paint supply for the tank efficiently. Selecting a smaller tank size then required will lead to more paint supply needs and will interrupt the application, and will not be feasible. On the contrary, in which bigger tank then required is selected means inefficient use of resources and will lead to higher running costs like fuel consumption.

Pointer: There is a pointer in the front of all machines, whatever scale they are, which provides straight line marking. Mechanical pointers, attached in front of the machines, parallel to road, works with the principle to referencing to stationary points on the road. This direction may be pavement borders or any other physical structure like previous markings. Besides, mechanical pointers, with high day visibility lasers can be used as pointer.

Truck chassis: Self propelled machines with their own propelling systems are designed specially for road marking; truck mounted alternatives can also be prefferred. Main element in selection of the truck chassis is to ensure that selected truck will carry the determines capacity’s equipment securely and effectively. For this, carry weight and the dimensions of the truck should be carefully evaluated.

White Lines, Saves Lives!

^TOP

is registered trademark of Yol Makina.

© Copyright MMXIV, Yol Makina